iwis smart connect

Outstanding expertise in engineering and production

We combine development and construction expertise to design and manufacture prototypes and tools as an important part of our range of services. Everything we do – from the original idea to the finished product – is a result of working hand-in-hand with our customers. We take particular care to

ensure optimum integration of prototype construction in our production process. Prototypes are developed for trials on our customers’ premises, and then computer simulations are used to design tools for day-to-day use and excellent products.

Development

Our customers define the task – we deliver the solutions. We always keep serial production in mind when assessing feasibility. Our employees design and develop the product in close cooperation and ongoing dialogue with the customer. They create operating instructions, test schedules and test reports.

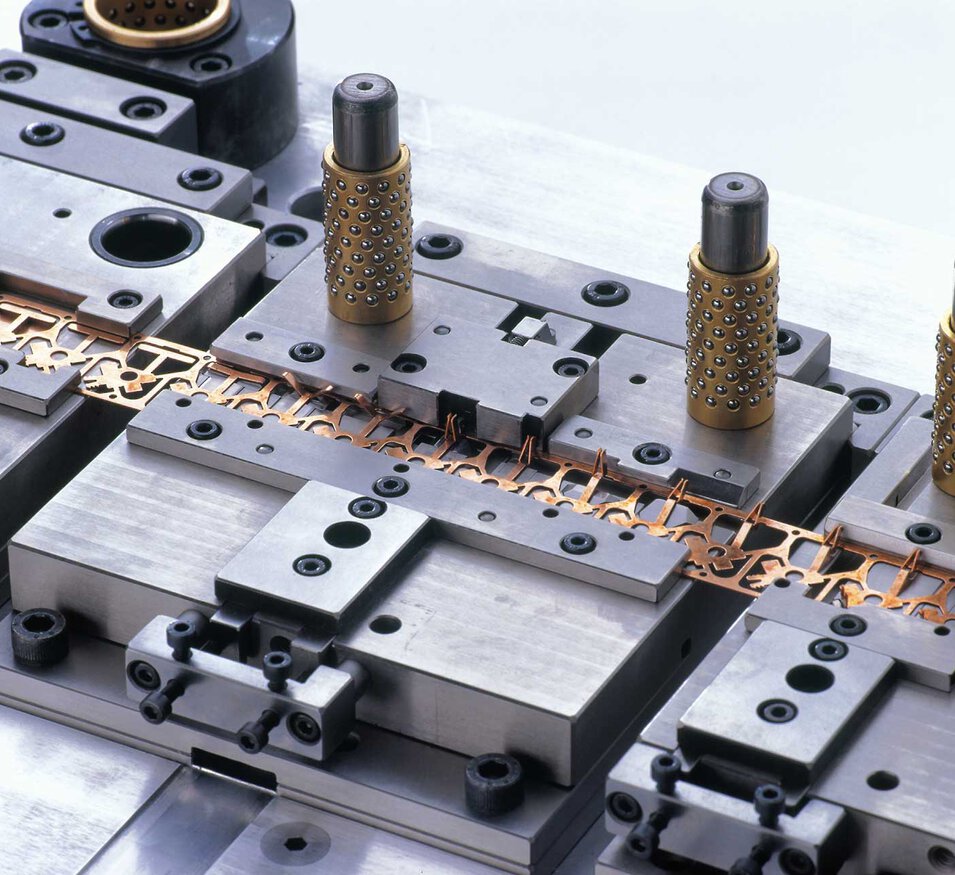

Toolmaking

Our in-house toolmaking department designs and manufactures soft tools, auxiliary tools and complex progressive tools with a length of up to 1,700 mm. All tools are maintained, serviced and repaired by highly qualified staff. Change requests can always be implemented during the ongoing manufacturing process.

Pilot series and small series production

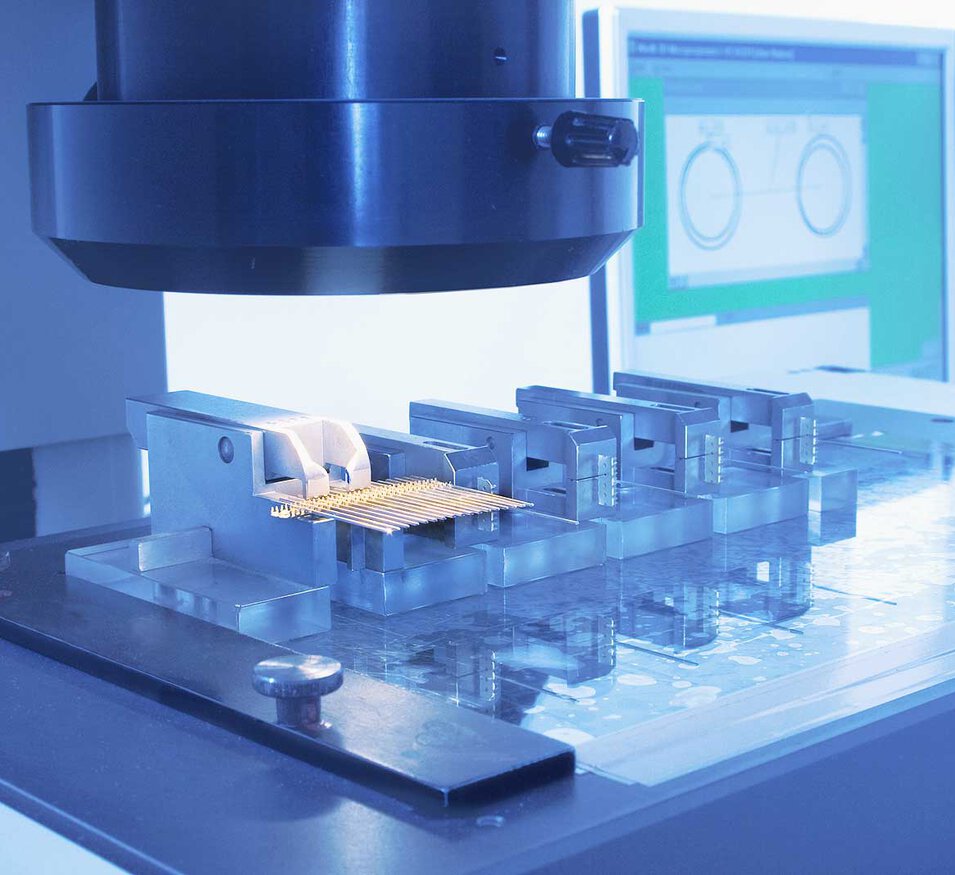

Our state-of-the-art CNC stamping and automatic laser machines allow multiple processing steps to be performed during a single clamping process. Edgers, grinders and deburring machines are available for subsequent processing operations. This manufacturing mode is ideal for the flexible production of small and medium-sized quantities.

Serial production

Our diverse range of automatic stamping machines with press forces from 25 t to 250 t is capable of handling different grades of steel, carbon steel, stainless steel, aluminium and non-ferrous metal alloys in thicknesses from 0.15 to 4 mm. Our experienced staff produces high-precision punched, bent and drawn parts on these machines.

Solutions partner

- Challenging process requirements

- Realization of customer batch sizes

- Up-front funding of tools and investments

- Perfect order and logistics processing with SAP

Development partner

- Product and process design

- Press-fit technology

- IDC technology

- Sub-assemblies

- Prototyping and laser cutting

- High-speed / multiple-fall tools

Production optimizer

- Adoption and optimization of customer tools

- Regular productivity progress

- Faultless process integration with minimal personnel

- Design, development and production of new tools

Only the very best technology – including machines

Transition from prototype to production is smooth and efficient: everything fits together from the start, because machines and feeds usually come from the same supplier. When it comes to high-precision stamping or bending/welding technology, we rely on the world market leaders Bruderer and Bihler, whose pioneering mechanical engineering guarantee maximum accuracy and process reliability, even when machines are running at full speed and capacity.

Bruderer – high vertical production range, consistent precision

Bruderer is the world market and technology leader for sheet-metal stamping and bending. iwis smart connect relies on dependable BSTA Series technology for high-precision stamping. In a wide range of applications, cycle rates of up to 2000 1/min can be achieved. The unique power transmission system ensures unrivalled precision and process reliability, while high-performance control units maximize the use of functionalities.

Bihler – superior stamping/bending technology

Bihler is a world leader in the field of bending/assembly/welding technology, whose ground-breaking machinery and systems solutions play a key role in numerous iwis process chains. High-volume, complex production tasks involving a wide variety of materials – ranging from steel to bright metal alloys – are performed on a daily basis.

The fast track from precision-made prototype to serial production

After completion of the initial development phases of a product, absolutely accurate prototypes and samples are required. We can significantly speed up the development process with the fast, efficient production of samples, prototypes, pre-series versions and serial-made articles.

Small and pre-series batches are manufactured with high repeatability accuracy and to the narrowest tolerances, and computer-aided functional simulations support the development work. Thanks to our prototype production facilities and equipment, and our engineers’ technical abilities and experience, high-precision assembly is assured.